How to Find Reliable Injection Molding Services in China

Well, the major meeting has just concluded. your new project has the green light, the timeline is aggressive, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. Savings can be substantial. However, your brain is racing with concerns. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Sourcing plastic mold company doesn’t have to be a gamble. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Here’s a practical playbook to nail it.

Step One: Do Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. Don’t assume a remote factory can guess your needs. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What belongs in your RFQ?

Begin with 3D CAD models. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. Here you specify what 3D can’t show. Think tolerances, material grades, finish specs, and any feature-critical notes. Call out smooth surfaces or precision hole sizes in big, bold notation.

Next up, material. Avoid generic terms like “Plastic.” Nor just “ABS.” Be specific. Call out SABIC Cycolac MG38 (black), for example. What’s the reason? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who will you target? The web is vast but overwhelming. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Treat them as initial research tools, not final solutions. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Perhaps hire a local sourcing specialist. They do cost extra. Yet top agents deliver reliable, audited suppliers. They handle local liaison and oversight. On your first run, this is like insurance. Consider it timeline insurance.

Another classic method? Trade shows. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. Plus, ask peers for referrals. Consult trusted colleagues. A recommendation from a trusted peer is often worth its weight in gold.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. bids begin to arrive. Some will be shockingly low, others surprisingly high. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It involves both metrics and gut feel.

First, look at their communication. Is their turnaround swift and concise? Do they communicate effectively in English? But the key: do they probe your RFQ? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. This is not optional. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. That small investment can save you thousands.

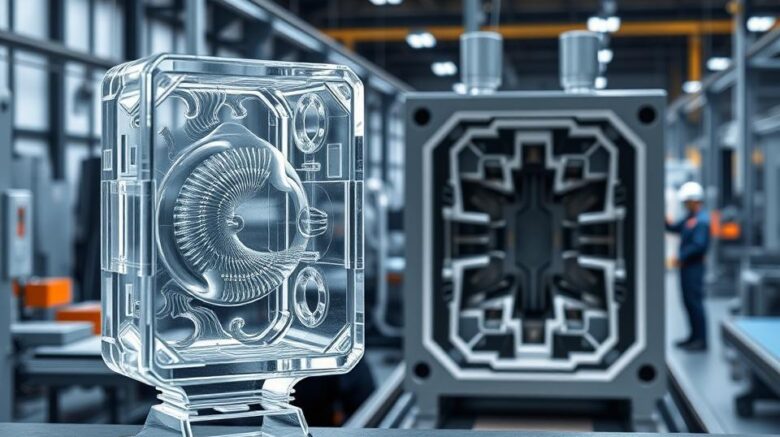

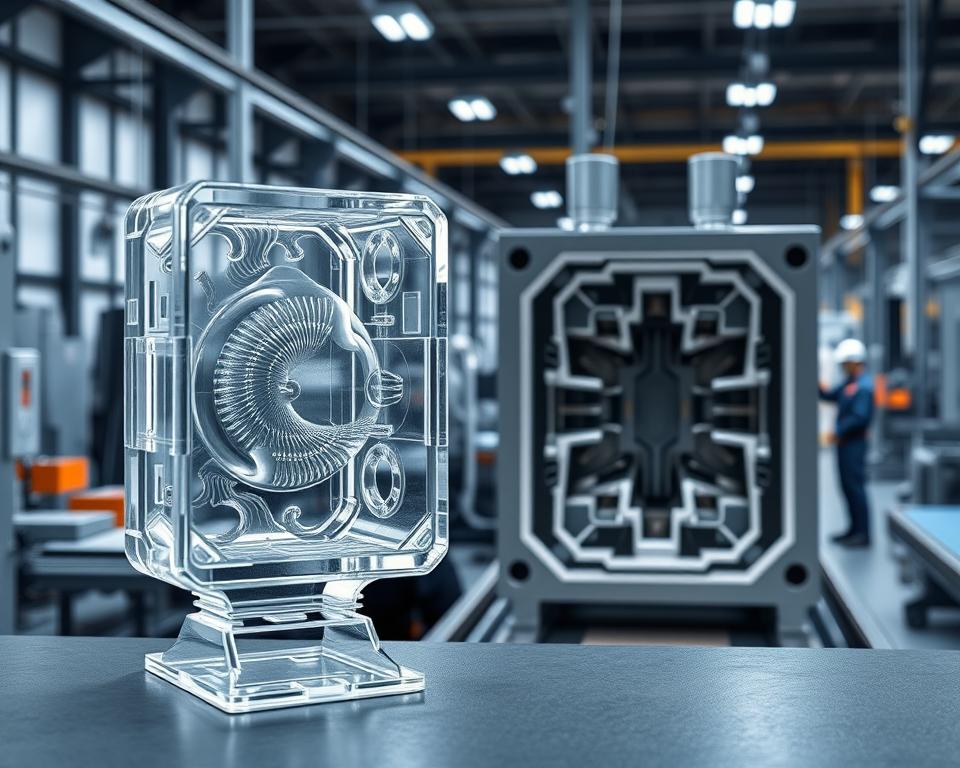

Transforming CAD into Real Parts

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. It’s your first real test.

T1 parts usually require adjustments. It’s par for the course. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold in China samples follow. This process might take a couple of rounds. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You sign off, and it serves as the master quality reference.

Completing the Sourcing Journey

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How do you maintain consistency for part 10,000?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Bring in an external QC firm. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Don’t forget shipping details. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? These choices hugely affect landed cost.

Sourcing from China is a marathon, not a sprint. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.